Heater Control

Over 4000 installations of units across the country to control the power input to heating elements in accordance with the control requirements. Digital designs are offered with very advanced and unique features such as recording, master slave operation, profile setting, communication etc.

Variations

- Analogue: Integral Cycle Control Up to 350A

- Analogue: Phase Angle Control Up to 3500A

- Digital: Integral Cycle Control Up to 350A

- Digital: Phase Angle Control Up to 3500A

- DC Output Rating Upto 5000A (Analog & Digital)

- Phase angle/ Integral Cycle /DC

- IGBT Based Convertor up to 8000A ( Digital)

- Various control algorithms such as voltage, current, power, Voltage square etc.

- 1∅ & 3∅ phase

- Different supply voltages and frequencies

- Linear and non linear loads

- Temperature, voltage, current, power control…

- Range of IP Classifications

- Supervisory Software

- Transformer primary control systems

Integral Cycle

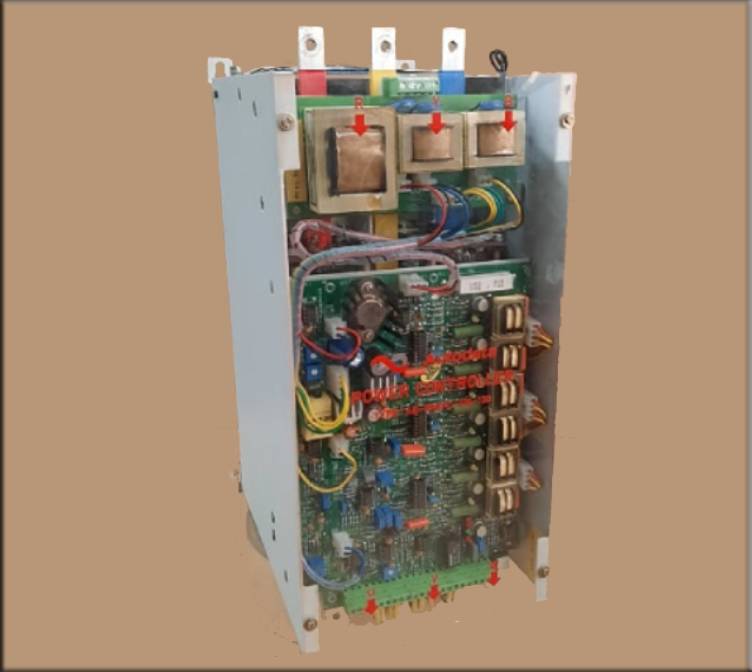

HCIC is the series of 1Ph & 3Ph analog heater controller units, using latest technologies and innovation to facilitate easy integration in control systems and ensure hugely impressive performance.

Features

- Integral type

- Current up to 350A for 3Ph

- Voltage up to 415 VAC/230VAC

- Reference input 4-20mA or 0-10V or Pulse type.

- Healthy, Trip indication with relay Form C contact – Optional with Extra Device

- Control Enable signal to start

- Built-in Heat sink temp sensing For Higher Rating

Application

- Metal Heat treatment

- Food Processing

- Furnaces

- Extruders

- High Temp furnace

- Glass Furnace

- Multi-channel Heaters

Phase Angle Phase Control

3PAPC is the Autodata series of advanced Analog Power controller units, using latest technologies and innovation to facilitate easy integration in control systems and ensure truly impressive performance.

Features

- Phase angle type

- Current range from 30A to 3500A

- Voltage up to 440V L-L

- Reference input 4-20mA or 0-10V or Local potentiometer.

- Current limit

- Trip current indication with relay Form C contact

- Control Enable signal to start

- Built-in Heat sink temp sensing

Application

- Metal Heat treatment

- Food Processing

- Furnaces

- Extruders

- High Temp furnace

- Glass Furnace

- Multi-channel Heaters

Celsius

Celsius controller is a TI DST based controller. Celsius is a Thyristor Power Controller with communication capability. It may be employed in any place where voltage, current or power has to be controlled or regulated in processing technology. Several modes of operation and control, good coupling ability to process and automation technology, high control precision by application of a32 bit RISC processor and simple handling ensure that Celsius is suitable for new applications as well.

Celsius is suitable for:

• Resistive Loads

• Glass Loads

• As primary Power Controller for a transformer with subsequent load

HTMS

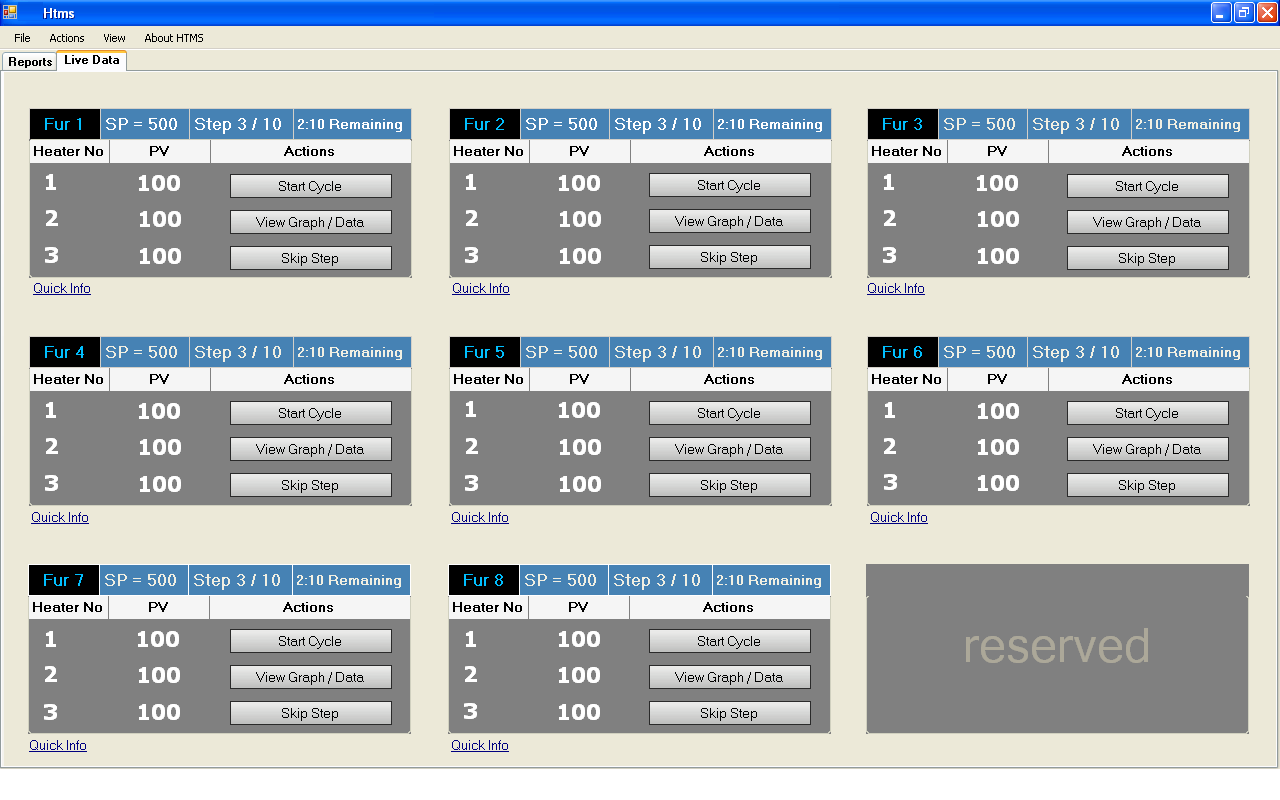

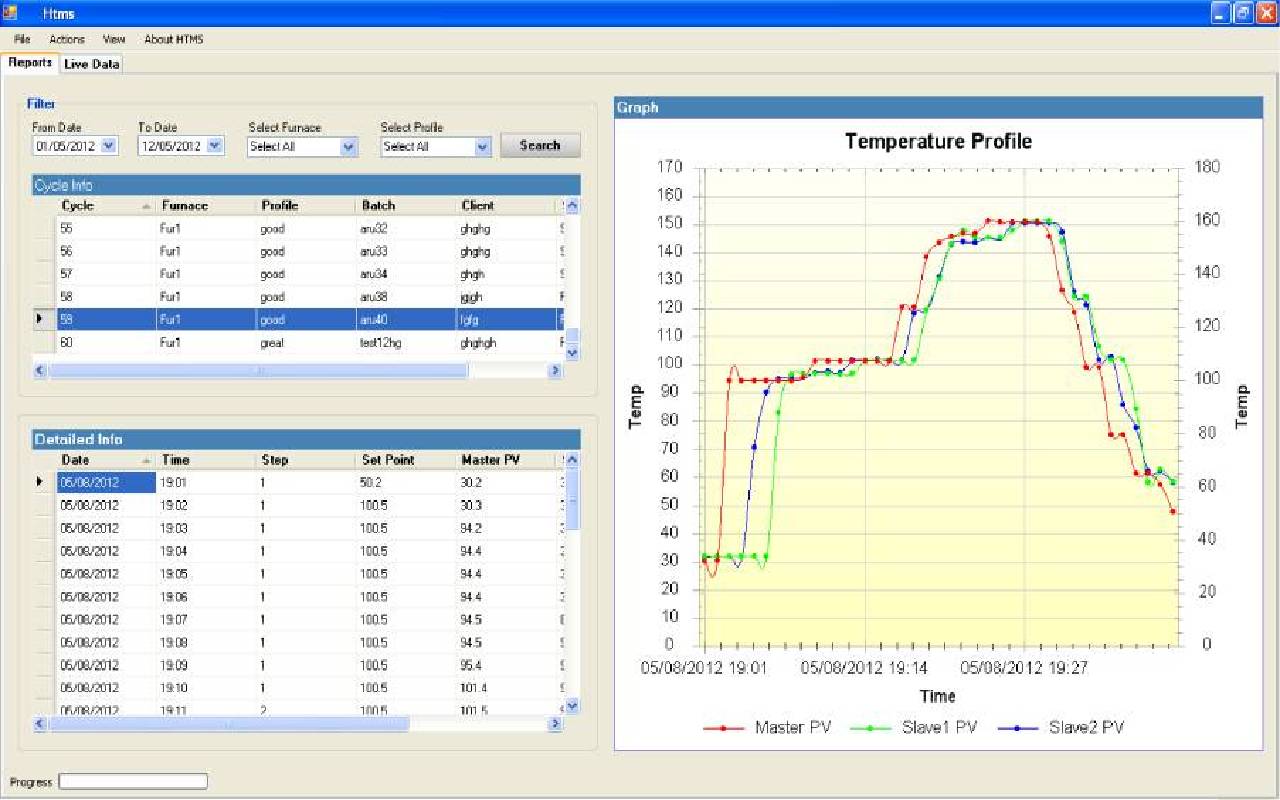

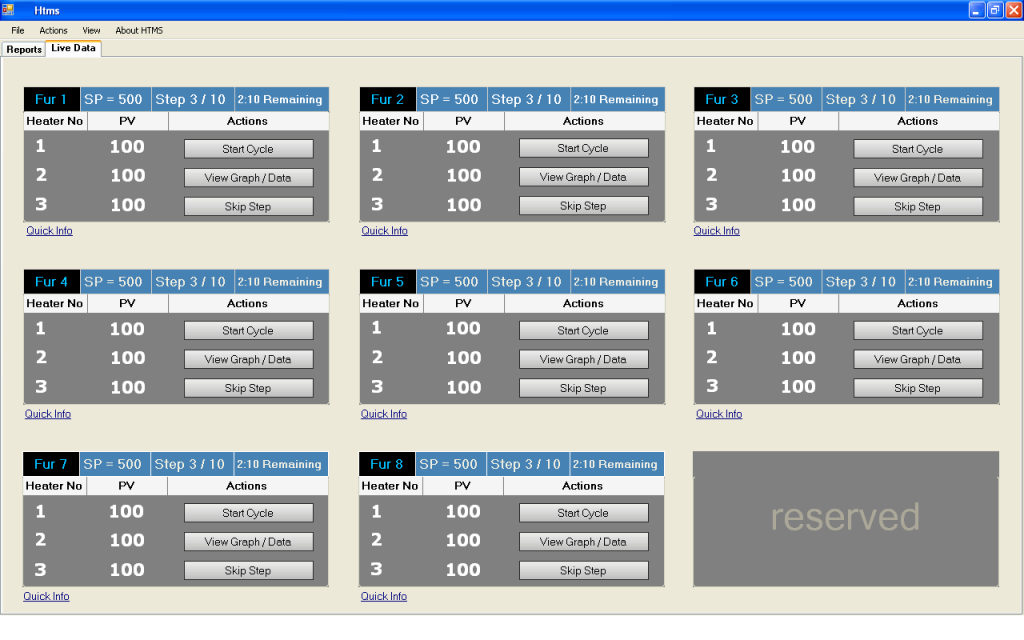

Unique software for Heat Treatment Process with different Profiles which optimizes the utilization of the entire heat treatment shop with multiple furnaces ensuring maximum throughput and detailed records of the individual heats with time temperature profiles of the set and actual values is maintained. Batch details, alarm history with date and time stamp history allows for detailed analysis and continuous improvements. The HTMS software has been developed after close association with heat treatment professionals and after hundreds of installations of Thyristor heater control systems. HTMS has been developed for all types of furnaces (Electric, Oil or Gas fired). This software enables centralized monitoring and reporting of the processes running in different furnaces.

A number of furnaces can be monitored from a single place. The details such as which stage each furnace is in, remaining time, details of the charges in individual furnaces, the plotting of the temperatures, the choice of the temperature time profile, utilization of the furnaces, consumption details etc. can be recorded for each charge. This system generates reports of the charge details, time stamp, Operator in charge, and temperature vs time profiles. This system can also be monitored from remote locations through web connectivity and data exchange with plant ERP software.

HTMS

The HTMS software has been developed after close association with heat treatment professionals and after hundreds of installations of Thyristor heater control systems. HTMS has been developed for all types of furnaces (Electric, Oil or Gas fired). This software enables centralized monitoring and reporting of the processes running in different furnaces.

A number of furnaces can be monitored from a single place. The details such as which stage each furnace is in, remaining time, details of the charges in individual furnaces, the plotting of the temperatures, the choice of the temperature time profile, utilization of the furnaces, consumption details etc. can be recorded for each charge.

This system generates reports of the charge details, time stamp, Operator in charge, and temperature vs time profiles.

This system can also be monitored from remote locations through web connectivity and data exchange with plant ERP software.

Configuration

Reliability

- Ratings of Power components are very conservative.

- No Derating for Higher Ambient Temperature up to 50˚C

- Nearly 4000 Units in operation. Many for 20+ years

- Suitable for Indian environments. Special executions that do not need air conditioning