Active Harmonic Filter

Active Harmonic Filters

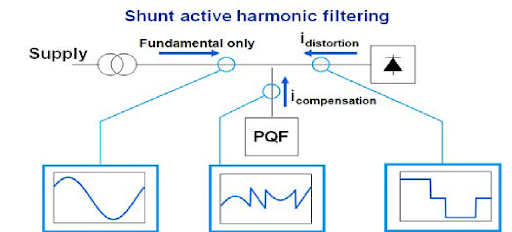

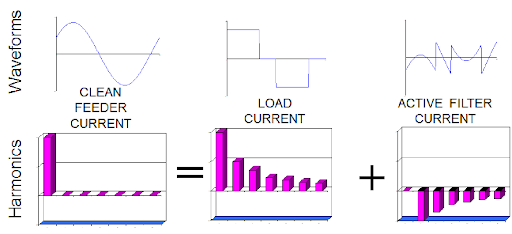

Active harmonic filters are parallel filters (which means the Load current doesn’t go through the filter) that are used to reduce, or mitigate, harmonics to tolerable levels as defined by IEEE-519.

These are Active Front End IGBT based topologies connected to the mains, to filter (or clean) the current wave by injecting inverse currents to cancel out the undesired harmonic components. Depending on the harmonic content, the load variation and budget it might be better to go in for a Hybrid Filter.

ADT Q2-series active harmonic filters are built on 3-level topology and are designed for light industrial and commercial buildings with voltage level up to 690V in both 3W and 4W applications. ADT P-series active harmonic filters are customized for demanding applications and are available from 480V up to 1000V. Equipped with state-of-the-art monitoring and reporting functionality, the robust ADT active filters operate in harsh environments and are easily scalable.

ADT Q2 Series AF is connected in parallel with non-linear loads, and uses one set of current transformers (CT) to detect the load current. It calculates each order harmonic current by FFT algorithms in its DSP microchips, and then generates a compensating current with the same amplitude but opposite phase angles to the detected harmonic current, which cancels out the original load harmonics.

The ADT Q2 series AF not only eliminates harmonic current from the load side, but it also mitigates harmonic voltage caused by harmonic currents. The AF system can also improve power factor (PF) and correct load imbalances in the power system.

Features

• Harmonic, reactive power and imbalance compensation

High harmonic filtering rate

• Up to 98%

Excellent reactive compensation

• High speed, Precise (-0.99≤PF≤0.99), Step-less, Bi-directional (capacitive and inductance) compensation

Excellent imbalance correction

• Both negative and zero sequence, mitigates neutral current

• Wide input voltage & frequency range, adapts to tough electrical environments

•Low thermal loss (≤3% of rated APF kVA), efficiency ≥ 97%

High stability

• Infinite impedance to grid, avoids harmonic resonance problems

• Modular design, embedded in standard or customized cabinet

Easy installation and maintenance

• Plug-in installation for APF module replacement and expansion

Wide capacity range

• 50A~150A for a single cabinet, up 10 cabinets in parallel

Environmental adaptability

• -10~50°C temperature, compatible with diesel generator

Complete protection

• Grid Over/Under voltage, APF over current, over temperature, and more. All faults are recorded in the event log, which is convenient for failure analysis

Technical Specification

Features

| Rated Voltage | AC 400V, AC 690V |

| Electrical Specification | |

|---|---|

| Input Voltage Range | AC 400V : AC 308V~480V AC 690V : AC 432V~880V |

| Electric Connection | AC 400V : 3P3W/3P4W AC 690V : 3P3W |

| Rated Frequency | 50Hz (60Hz) +/- 10% |

| Input Voltage THD Range | ≤15% |

| Rated Current per Module 100Amp | AC 400V : 50Amp, 75Amp AC 690V : 100Amp |

| Rated Current per Cabinet (module combination) |

AC 400V : 50~525Amp AC 690V : 100~500Amp (module combination) |

| Redundancy | Each module is an independent filtering system |

| Harmonic Elimination Range (Selectable) |

AC 400V : 2rd ~ 50th order AC 690V : 2rd ~ 31st order |

| Harmonic Filtering Degree | 0 ~ 100% programmable per harmonic in Ampere value |

| Harmonic Filtering Performance | Filter up to 98% harmonics at rated load, THDv<3%, THDi<5% after filtering |

| Reactive Power Compensation | Both inductive and capacitive reactive power |

| Imbalance Correction Capability | AC 400V : Mitigate negative and zero sequence AC 690V : Mitigate negative sequence |

| Full Response time | <20ms |

| Instant Response time | <100us |

| Thermal Loss (kVA) | ≤3% of APF rated capacity |

| Output Current Limitation | Automatic (100% rated capacity) |

| Parallel Expansion(System) | AC 400V : Up to 10 Racks(7 modules per cabinet) AC 690V : Up to 10 Racks(5 modules per cabinet) |

| MTBF | >100,000 hours |

| Control Technology | |

| Switching Frequency | AC 400V - 50A, 75A : 60kHz AC 400V - 100A : 30kHz AC 690A : 20kHz |

| Controller | DSP control |

| Communication | Modbus Protocol, RS232/485 |

| Monitoring (Optional) | PQC Monitor Software |

| Physical Specification | |

| IP Grade of Cabinet | IP20, IP30 or customization |

| Cooling method | Intelligent forced air cooling |

| Noise Level | AC 400V : < 65dB(A) @1m (Module)

AC 690V : < 70dB(A) @1m (Module) |

| Environmental Requirement | |

| Ambient Temperature | -10~50 ℃ |

| Relative Humidity | 0~95% |

| Altitude | ≤ 1000m Rated Capacity,1000-2000m (derating 1% per 100m) |

About Autodata

Autodata is established manufacture founded in 1981, India. We are committed towards latest technology by developing globally competitive products and achieving worldwide success. As a true manufacturer, we are driven by an ambition to deliver highest standards of product quality in an industry to gain customer’s satisfaction.

- Quality Control System, 100% Satisfaction Guarantee

- Highly Professional Staff, Accurate Testing Processes

- Unrivalled workmanship, Professional and Qualified

- Environmental Sensitivity, Personalised solutions